Work Flow

CORRUGATED BOARD PRODUCTION LINE

(THE FOLLOWING ARE CARTON BOARD PRODUCTION, HERE LEARN PRINT SLOTTER.)

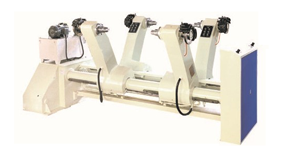

HYDRAULIC/ELECTRICAL SHAFTLESS MILL ROLL STAND

HYDRAULIC STATION MOTOR /ELECTRICAL MOTOR DRIVE, EXPANDING CHUCKSOPEN-CLOSE,UP-DOWN, RIGHT-LEFT ADJUSTMENTS OF ARMS ARE OPERATED BY HYDRAULIC/ELECTRICAL SYSTEM. DOUBLE WORK POSITIONS

BRAKE DEVICE ADOPT THE STANDARD OF CAR INDUSTRY, MULTI-POINT BRAKE DISC IS DELICATE, FORCE EQUALITY, STEADY, LONGEVITY, SIMPLY REPLACED, WHICH CAN BE BOTH MANUAL-CONTROLLED AND SPLICER-CONTROLLED

TROLLEY & TRACK

TRACKS MADE OF ROUND STEEL, DIA 20MM,GIRDER MADE OF 16# CHANNEL STEELPANEL OF THE TROLLEY IS MADE OF 10MM ARMOR PLATE BY PRESSING, ASSEMBLED BY WELDED

SINGLE FACER

FINGERLESS VACUUM SUCTIONUPPER CORRUGATING ROLL AND LOWER CORRUGATING ROLL MADE OF 48CrMo, INTERMEDIATE FREQUENCY TREATMENT. SURFACE GRINDING AND CHROME-PLATED, HARDNESS MORE THAN HRC55

UPPER CORRUGATING ROLLS AND LOWER CORRUGATING ROLLS CAN BE INSTALLED AND REMOVE AS A UNIT, EASY TO BE CHANGED

EQUIPPED WITH PRE-HEATER ROLL FOR LINER AND STEAM SPRAY DEVICE FOR MEDIUM

ADD PAPER GUIDE ROLL BEHIND THE STEAM SPRAY DEVICE, WHICH MAKES THE INTERFACE BETWEEN MEDIUM AND CORRUGATING ROLLS DECREASED, AND PROLONGS THE LIFE OF CORRUGATING ROLLS.

WITH FREQUENCY CONVERT MOTOR TO MAKE STEPLESS SPEED REGULATION AND SYNCHRONIZED LINKAGE WITH FOLLOWING MACHINES.

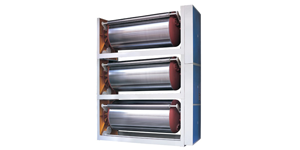

PREHEATER

MADE ACCORDING TO NATIONAL STANDARD OF PRESSURE VESSEL I, ALL ATTACHED INSPECTION CERTIFICATE. SIDE BOARD MADE OF CAST IRON BY PROCESSING PAPER GUIDE ROLLS. THE PARALLELISM OF THE TRAVEL PAPER GUIDE ROLL CAN BE ADJUSTEDSURFACE CAN BE ROTARY-ADJUSTED ACCORDING TO THE ABRASION DEGREE DISH-LIKE END PLATE OF THE CYLINDER BODY MAKES PAPER HEATING EVENLY.

OVERHEAD BRIDGE CONVEYOR

WITH SAFETY RAILS, STAIRCASES AND BOARD TO INSURE OPERATOR SAFETY AND ALSO MAKE EASY TO OPERATEALL STRAP AXLE AND PAPER GUIDING ROLLS SURFACE ARE CHROME-PLATED

DOUBLE GLUE MACHINE

GLUE TRAY MADE OF STAINLESS STEEL, RUST-RESISTANCE, EASY TO CLEAN.GLUE ROLL IDLING SLOWLY TO AVOID THE GLUE DRY.

THICKNESS OF GLUE DIGITAL DISPLAY, ADJUSTED BY COMPUTER. THICKNESS AUTO ADJUSTMENT PLC CONTROLLED.

LIFT OF PRESSURE ROLL CONTROLLED BY AIR CYLINDER.

DRIVEN BY FREQUENCY CONVERSION MOTOR, WHICH SYNCHRONIZED LINKAGE WITH THE DOUBLE FACER, UPPER AND LOWER SYNCHRONIZED.

DOUBLE BACKER

CONVEY BELT TENSION CONTROL DEVICE, OIL PRESSURE LIFT DEVICE INSIDE.HEATING PLATE SURFACE GRINDED AND CHROMED, ACCORD WITH NATIONAL STANDARD OF PRESSURE VESSEL I, ALL ATTACHED INSPECTION CERTIFICATE.

GOOD STEAM TUBES POSITION, TEMPERATURE CAN BE ADJUSTED BY GROUP HEATING PLATES.

CONSISTS OF HEATING-CONGLUTINATE SECTION AND COOLING-SHAPING SECTION HEATING-CONGLUTINATE SECTION

NC SLITTING SCORER

SLITTING CAPACITY: 3 OUTS (SLITTING TOOL 4 SCORING TOOL 6), 4 OUTS (SLITTING TOOL 5, SCORING TOOL 8), 5 OUTS (SLITTING TOOL 6, SCORING TOOL 10).THE MACHINE CAN MOVE RIGHT OR LEFT WHICH CONTROLLED BY ELECTRIC MOTOR.

THE ADJUSTMENT FOR UPPER SLITTING AND SCORING TOOLS IS CONTROLLED BY PNEUMATIC SYSTEM AND ORDERS CAN BE EASILY CHANGED DURING THE MACHINE RUNNING WITHOUT STOPPING IT.

DELIVERY AND COLLECTION

TWO HORIZONTAL DELIVERY SECTION AND ONE SIDE VERTICAL DELIVERY SECTION. HORIZONTAL DELIVERY SECTION CONTROLLED BY ELECTROMAGNETIC SPEED ADJUSTMENT MOTOR, MANUAL STEPLESS SPEED REGULATION, BELT FOR THE SECOND HORIZONTAL DELIVERY SECTION WILL STOP WHEN SIDE DELIVERY SECTION DELIVERY THE SHEETS TO AVOID SHEETS DISORDER, SIDE VERTICAL DELIVERY SECTION CAN BE PUSHED UNDER THE HORIZONTAL DELIVERY SECTION TO MATCH SHEET LENGTH.GLUE MAKING SYSTEM

STEAM PIPING SYSTEM

AUTOMATION CONTROL STATION AND CONTROL PANEL

Standard Work Procedures

Contact us

ORDER

LIST

factory inspection

shipment

Delivery

user site installation

One year

warranty