Work Flow

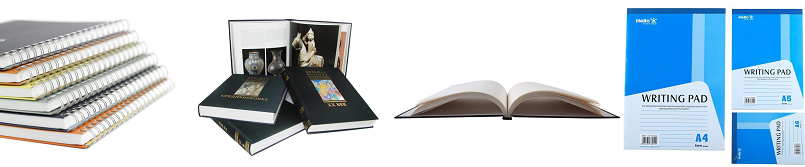

Book/Exersice Notebook Print and Postprint Machines

Design Work

-outside and inside content (letters and images)-Paper Size/Printing Color

-Hard Cover or normal cover

Print Plate

-Manual Film is traditional way, Now CTP is another option-Digital Printing Professional ways is fast in research

Print Press

-Offset is normal way; many comes to flexo and inkjetPost Press

-After Printing, now mostly need other treatment according to customer request such as UV coating, Laminating, Foil stamping, Die cutting, Embossing, etcBook Making

-Paper is ok now, what is the next step? Paper cutting, Paper folding, Pages collating/Gathering, Sewing or Glue Binding or Stitching or Double Spiral Wiring, Three-Knife Cutting, Pressing, Delivery. Normal Book is ready! If the book is hardcover book, need prepare the hardcover first and then case-in the book content part in hard cover.-Do all the procedures may work in one machine or separate machines? Now one not very thick book with normal cover, now work with one machine is possible. But most Printing Press companies use separate machines to meet different customer requests and the separate machines investment is less than the one-piece machine.

Machine Recommendation

-UV CTP Machine-Offset Printing Machine

-UV Coating, Laminating,Die Cutting, Foil Stamping Machines

-Paper Guillotine line, Paper Folder, Book Collator, Book Sewing/Stitching/Binding/Double Spiral Wiring, Three-knife cutting, Hardcover making, Case-in Machines

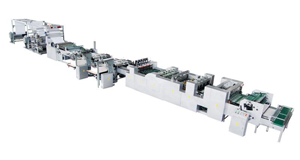

Automatic Machines Recommendation

-Roll Paper into Book Automation Line including flexo print, paper cutting, collating, stitching, folding, cutting and slitting function units.-Exercise Notebook/pad Automation Line

-Book Collating/Gathering Automation Line

Standard Work Procedures

Contact us

ORDER

LIST

factory inspection

shipment

Delivery

user site installation

One year

warranty